Alternative for no longer produced LINDAPTER F2 type assembly

LINDAPTER Eyebolt Nut Clamp assembly

Type F2

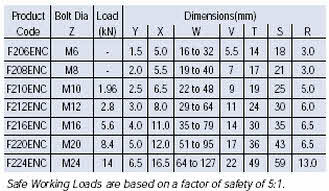

( Concerns product codes F206ENC, F208ENC, F210ENC, F212ENC, F216ENC, F220ENC and F224ENC )

On placing a recent order at the Lindapter company for their M16 type F2 complete eyebolt nut clamp assemblies, we were informed that the factory has discontinued manufacture and distribution as per July 17th 2007.

Because there is no compatible alternative for pressure vessels within the current Lindapter programme, we had to source elsewhere for compatible replacement parts, to fit on existing equipment, notably our older pressure vessels.

We are now pleased to offer as replacement spare parts a choice of two alternative metric size combinations, fitting your existing equipment.

In comparison to the F2 types both alternatives offer increased admissible tensile strenght.

Our Alternative I has almost identical measurements as the F2 types, thus will most likely require no alterations to your equipment.

Our Alternative II is our recommendation for any critical application.

For further information please call, fax or e-

A. GEZANG & CO BV -

Tel. +31-

ALTERNATIVE I :

For non-

(e.g. to secure lid on vessel, that is used for pressures under 0.5 bar; inspection lids, tanker lids etc.):

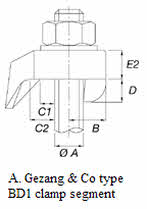

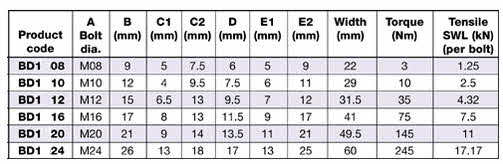

We supply complete combinations for metric sizes M8, M10, M12, M16, M20 and M24: Eyebolt (various lengths) + segment BD-

Example: Eyebolt M16 (steel class 4.6) length 110 mm + DB-

For further details, prices and delivery-

E-

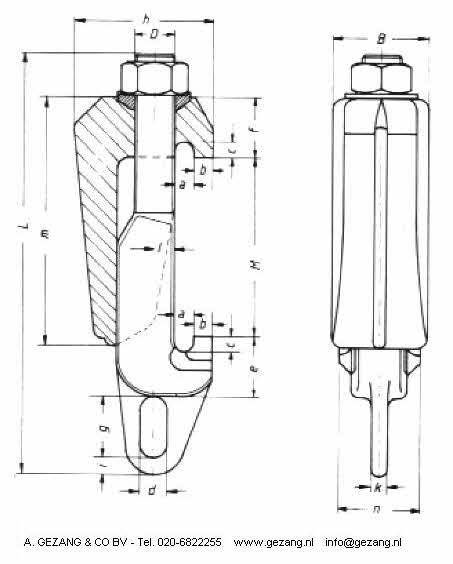

ALTERNATIVE II:

For critical applications :

Here both segments together form one set of jaws, tightening the rim of the lid onto the rim of the vessel (see sketch). The oval shaped eye on the bolt-

The segments are made of drop forged steel in: Quality class 5 = steel ck35, material no. 1.1181; Quality class 8 = steel 34Cr4, material 1.7033; Quality stainless steel A4 = steel X6CrNiMoTi17 122, material no. 1.4571 (= AISI 316Ti).

Available in metric sizes : M10, M12, M16, M20, M24, M27, M33, M42 and M56.

Example: two-